By Craig Monger

The semiconductor chip shortage affecting the production of computers, appliances, and automobiles is creating an unexpected headache for law enforcement in Alabama and beyond. They are unable to get patrol vehicles they have already ordered.

Police departments are competing for new vehicles with the entire country, which means they are having a difficult time keeping their fleets stocked with vehicles, resulting in recruits being unable to get patrol vehicles in some cases.

Jefferson County Sheriff Mark Pettway has felt the shortage firsthand. He said the sheriff’s office is waiting for nearly 100 vehicles.

“We have a backorder of vehicles right now,” Pettway said. “We just made another order of vehicles because our fleet needed to be replenished. We’re hoping that these chips that are missing from the vehicles will be furnished and placed in vehicles so we can get our vehicles put in service. Without these vehicles, we can’t respond.”

Pettway said the shortage could create a real public safety issue.

“We’re waiting just like everybody else,” said Pettway. “We are trying to make sure we maintain the vehicles we do have to make sure we can remain in service to the community, but I don’t know what else we can do right now.”

Mobile County Sheriff Sam Cochran has had similar issues in providing vehicles for his department, but the challenges associated with the global pandemic reach further than that.

“This is the most challenging time of all between the COVID, the shortages and the anti-police movement, and the shortages of employees and the difficulty recruiting, hiring and retaining,” Cochran said.

Cochran said his department has been waiting on new Chevrolet Tahoes, and he was told the vehicles wouldn’t be available until the latter part of 2022.

Certain manufacturers produce vehicles to fit the needs of police departments, such as increased engine performance and modularity for specialized equipment. Cochran said the sheriff’s department would have to purchase some Dodge vehicles to keep his force on the streets during the shortage. He said the switch to a different make could mean difficulty with the installation of equipment.

“We’ve never used Dodges before, but we just agreed to buy 10, which I didn’t want to do,” said Cochran. “But those are the only vehicles we could get right now, and we didn’t want to get caught short. Some of the equipment will not be transferable, so we will be stuck with the equipment when we wear them [the Dodges] out.”

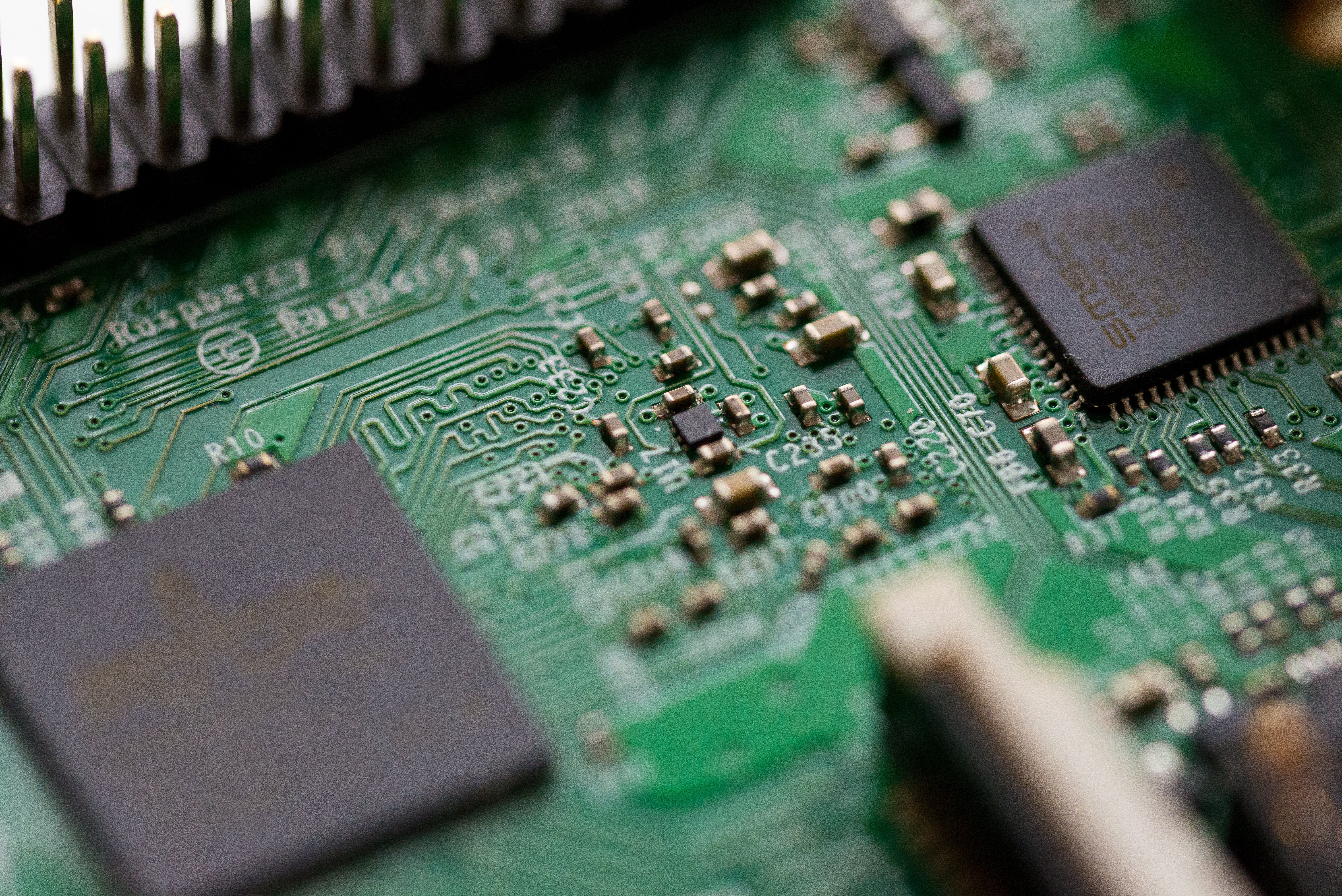

There is scarcely an appliance, electronic device, or vehicle that does not contain some form of semiconductor, also known as a “microchip.” These “chips” allow for the controlled supply of billions of nanoscopic electric currents to flow through an electronic system, allowing it to function properly. This controlled relaying of electric currents is what allows intercommunication within an electronic device.

Virtually every single electronic device and supporting infrastructure requires multiple semiconductors to function. Due to the supply chain issues that are negatively affecting the nation, these invaluable chips are in extremely short supply.

The chip shortage has aggressively impacted the auto industry. According to multiple reports from AlixPartners, a business and economics reporting agency, during the COVID–19 pandemic, people were forced to begin working from home at a drastic rate. People began to purchase electronic devices to make the process of working at home more expedient. People also stopped using their vehicles as much: no work commute, no dining out, no social functions, etc. When new car sales dipped, manufacturers put a hold on chip orders.

The dip did not last as long as manufacturers had predicted, and when they attempted to resupply, the suppliers were already experiencing shortages due to increased demand in other industries. The increased demand for electronics, combined with manufacturing plants being shut down, a global breakdown in distribution, and the general lack of workers, has led to the most significant shortage of chips in American history. AlixPartners expects the problem to continue into the second quarter of next year. According to Tim Yost, a marketing director at AlixPartners, chip shortages will cost the auto industry $210 billion in revenue this year.

The chip shortage has also caused the price of vehicles to increase. According to General Motors Chief Executive Mary Barra, the prices of GM vehicles have risen 20%.

The state of Alabama has been impacted by the global shortage. The Hyundai plant in Montgomery has halted production several times since June due to the shortage. The plant hit a 15-month low in the month of September, the lowest since a partial assembly line closure due to COVID in June 2020.

Mercedes, Honda, and other auto manufacturers are experiencing the same challenges and showing similar drops in production. Relief isn’t expected until 2023.